- +++ CIDAN MACHINERY GROUP ACQUIRED THALMANN +++

- +++ CIDAN MACHINERY GROUP ACQUIRED THALMANN +++

- +++ CIDAN MACHINERY GROUP ACQUIRED THALMANN +++

- +++ CIDAN MACHINERY GROUP ACQUIRED THALMANN +++

Thalmann

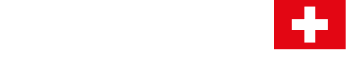

Sustainable increases in efficiency and permanent cost reductions, these are the key benefits of Thalmann‘s innovative long folding technology in sheet metal profile production.

In close cooperation with our international customers we ensure that customer needs are at the center of our attention. We at Thalmann continuously bring innovative solutions to the market, innovations that provide customers with measurable added value, higher profits and clear competitive advantages.

Imaginative, powerful and full of drive, this is the spirit that Thalmann customers and business partners have appreciated since 1960. Working with our modern long folding machines customers will not only experience the cost-effectiveness, our machines are also simply a pleasure to operate.

Thalmann Maschinenbau AG from Frauenfeld (Switzerland) is one of the world‘s leading companies in long folding technology.

Swiss Made

Quality, precision, safety, reliability and innovation, these benefits are associated with SWISS MADE. For Thalmann, as a Swiss company, they are essential, they shape our actions.

Machines

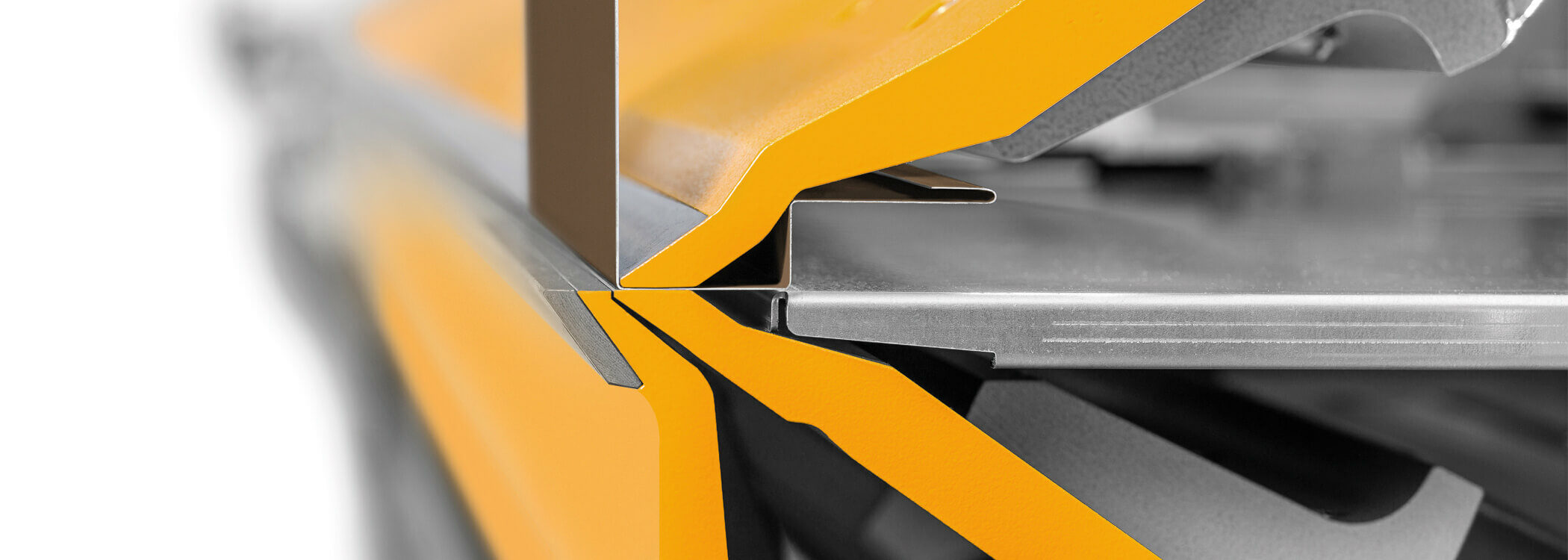

Thalmann’s product portfolio is based around three core products for folding sheet metal up to 3 mm. The TZ single folder is suitable for roofers and architectural applications, the TD double folder is suitable for roofers, architectural applications and industrial processes that require high throughput. The TC double folders are suitable for heavy duty folding of 3 mm sheets at high processing speeds.

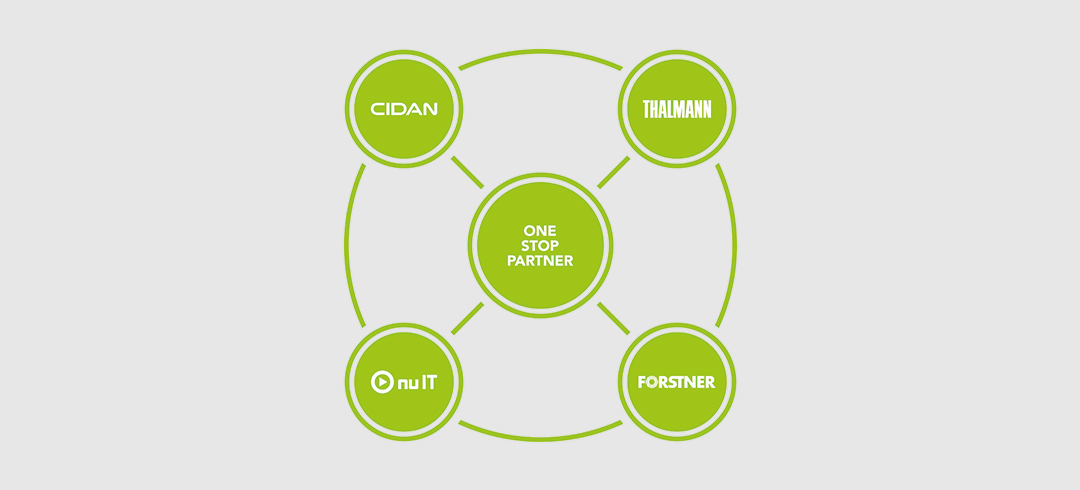

Within this product portfolio Thalmann offers a wide range of solutions, from fully automated flipping and sideloading units, to a fully automated and integrated slitting, feeding and folding line: "The Base", offered in cooperation with Cidan Machinery group.

Machines can be fitted and costume designed with different accessories such as roll forming and slitting units, loading tables, different gripper designs and configurations and different tool geometries.

Innvovations

Thalmann’s innovative strength and know how is the basis for customers to operate profitably and to give them clear competitive strengths and advantages.

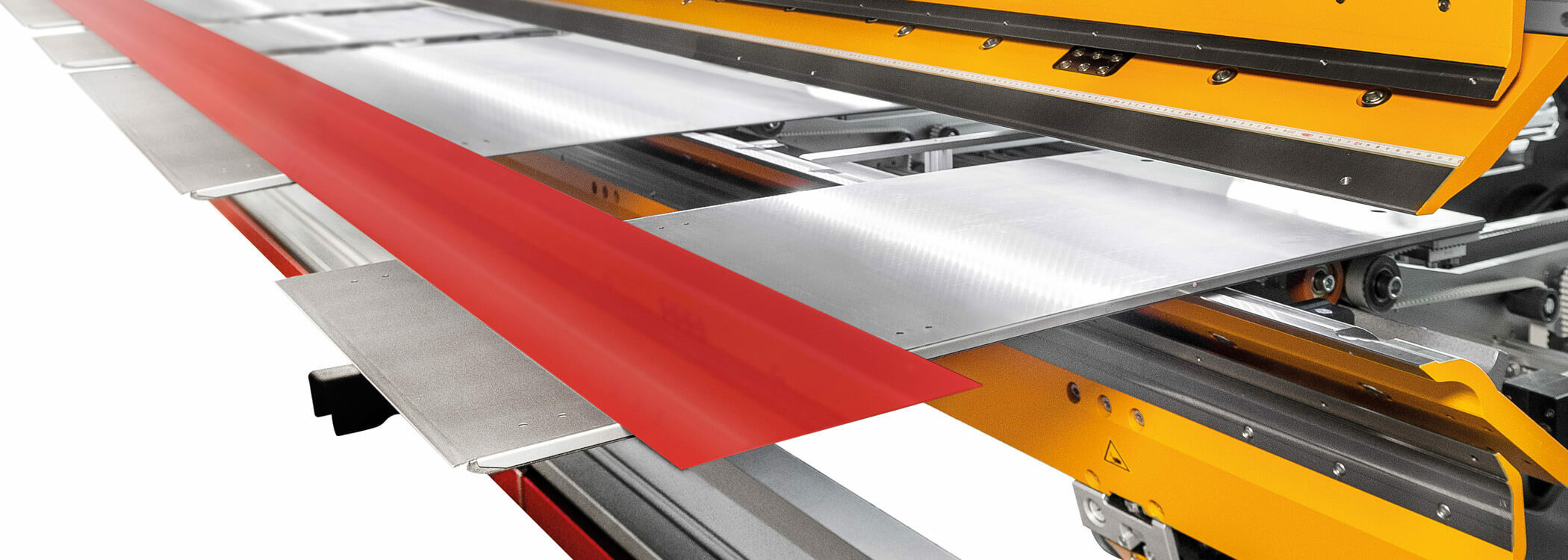

Thalmann innovations include a range of modular automation solutions such as 1. automated sheet metal loading, 2 .automated sheet metal flipping and 3. automated sheet metal unloading. By opting for these solutions on a Thalmann machine, operational costs in particular can be significantly reduced.

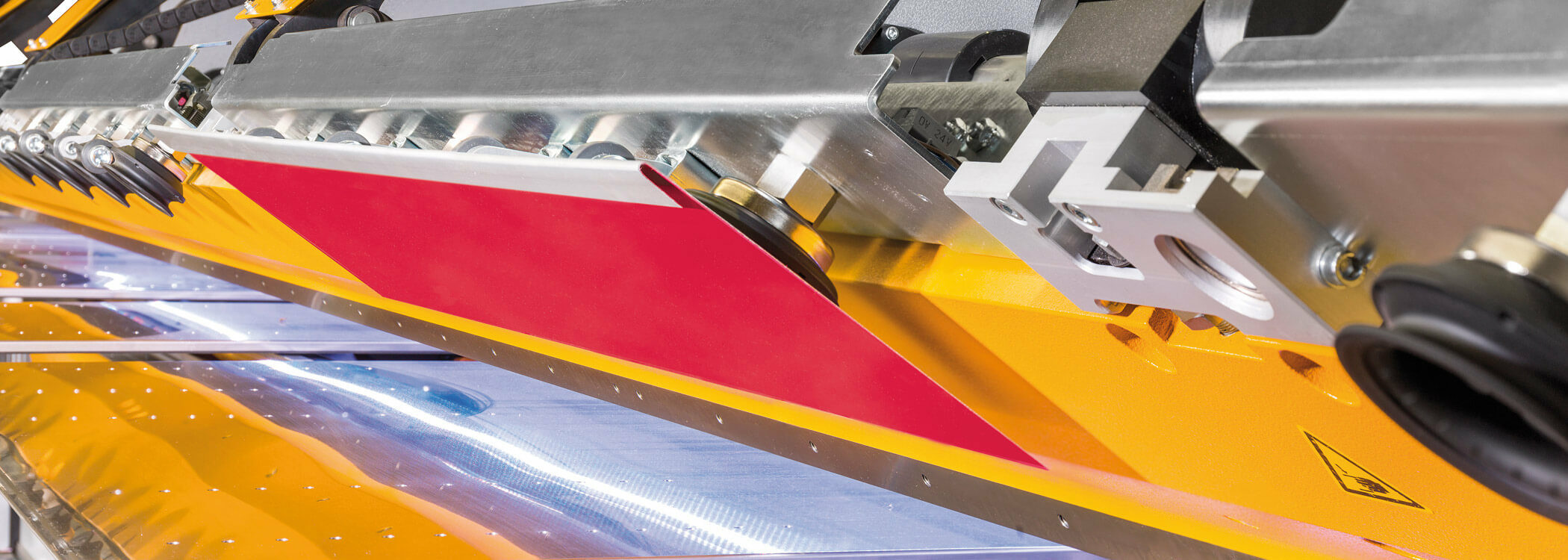

Modular tool shapes provide increased folding freedom and greater flexibility. Thalmann unique kinetic control shaft technology ensures high and constant folding precision. With the dynamic crowning function, an even higher folding precision can be achieved. The optimal clamping force transmission is guaranteed by the vertical force drive (VFD).

These are a selection of innovative highlights that have proven their value at numerous Thalmann customers worldwide.

Automation

Automation of industrial processes will be the next challenge for the sheet metal forming industry. We at Thalmann have made significant steps to meet Industry 4.0 standards. We are meeting these standards through proprietary developments and collaborations with different business partners.

The automation solutions has proven to increase operational efficiencies for our customers. The development of “The Base” jointly with Cidan Machinery group, is a fully automated sheet metal bending operation that includes a de-coiling and slitting line that allows bending operations to work without an operator at the production line.

Thalmann-Eagle

Why does a Swiss mechanical engineering company like Thalmann have an eagle in the company logo?

The eagle is more than just a concise symbol. We at Thalmann associate the eagle with properties that you will also find in our folding machines:

Speed, dynamic, precision, effectiveness and aesthetics.

The eagle also stands for vision, freedom, courage and power. We at Thalmann associate ourselves with this. We invest a considerable part of time and resources in the development of innovative solutions that create real benefits, added value and competitive advantages for our customers.