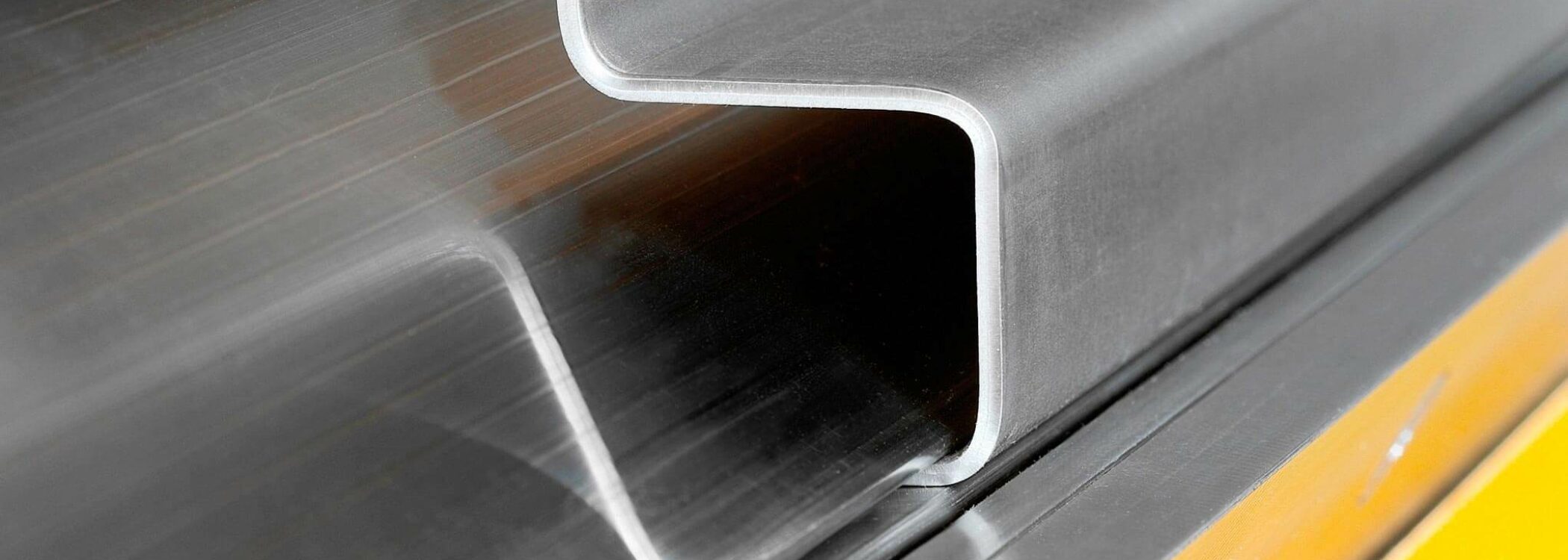

TC Double Folder

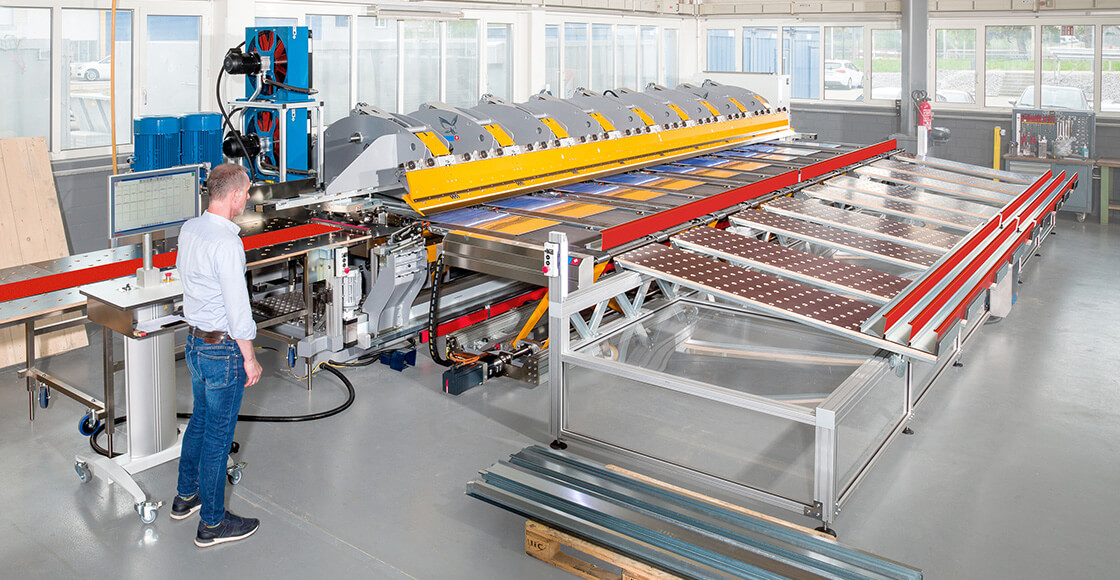

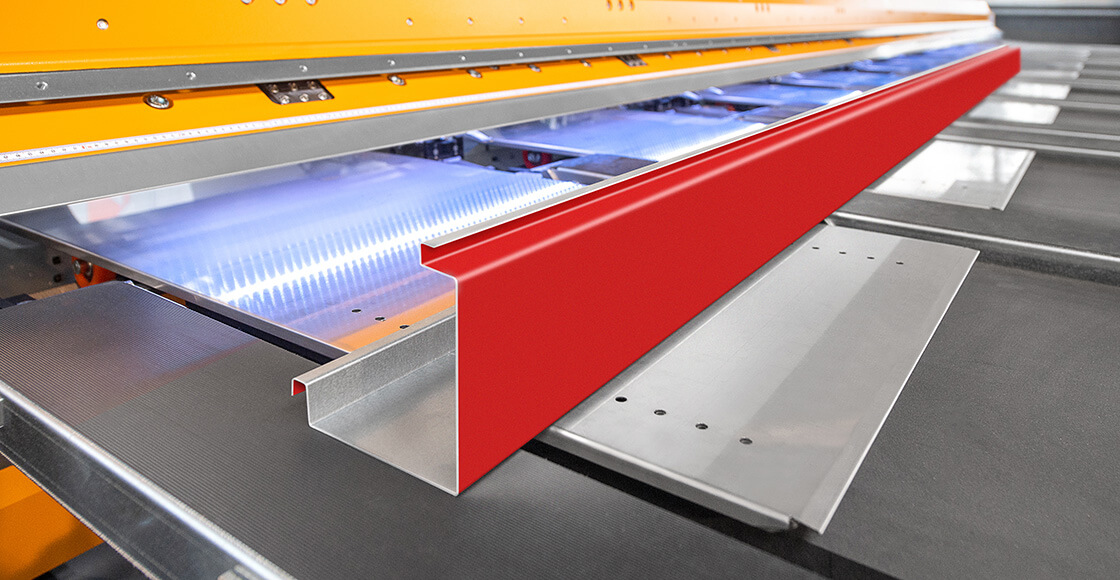

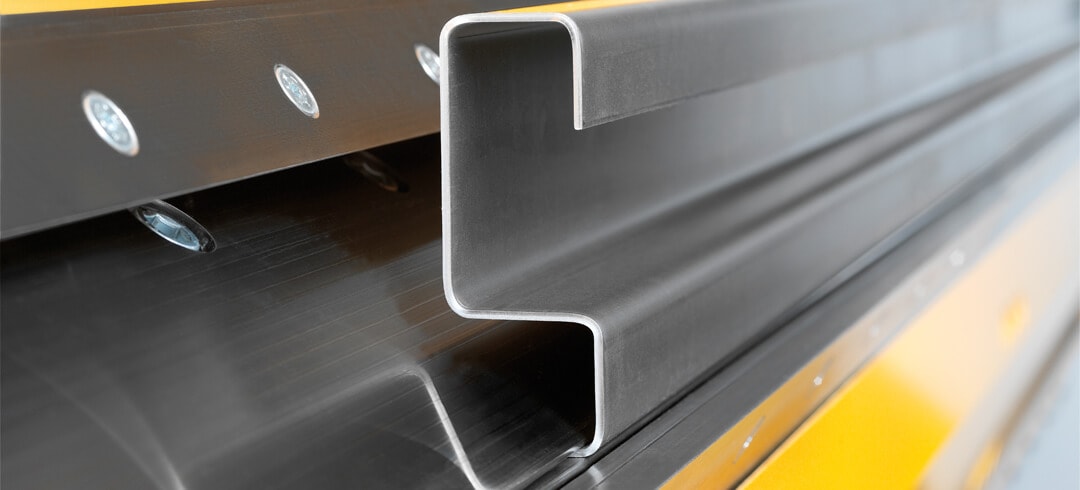

For the precise high-performance folding of thick sheet metal profiles, the TC double folder was developed.

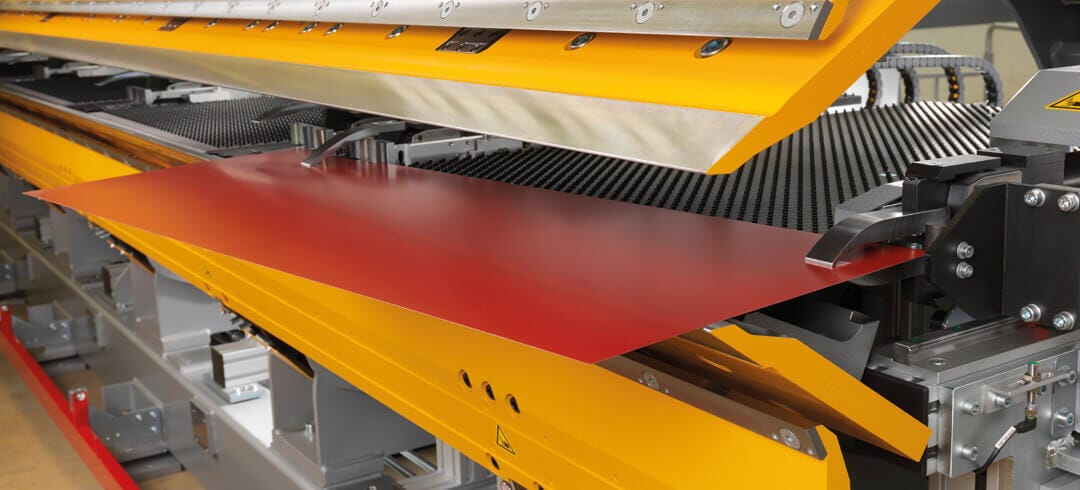

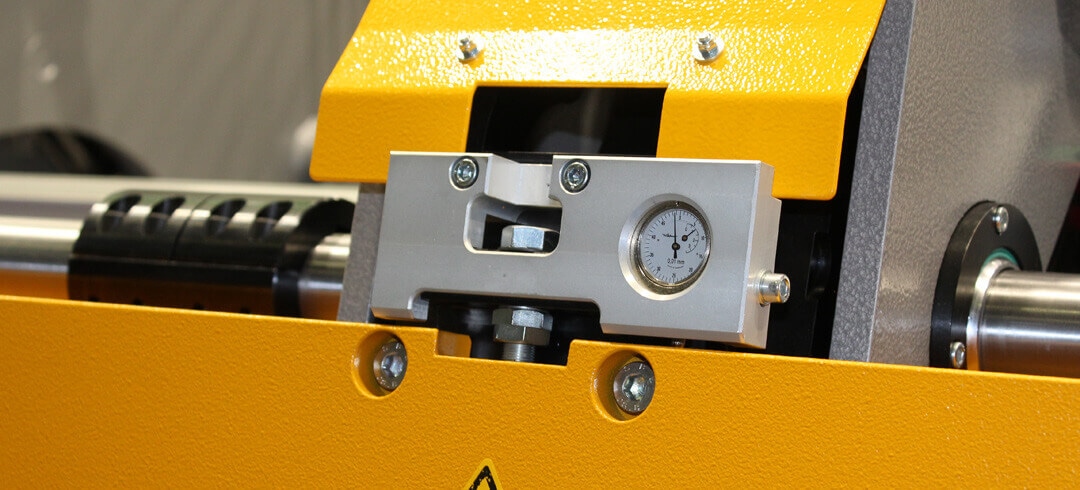

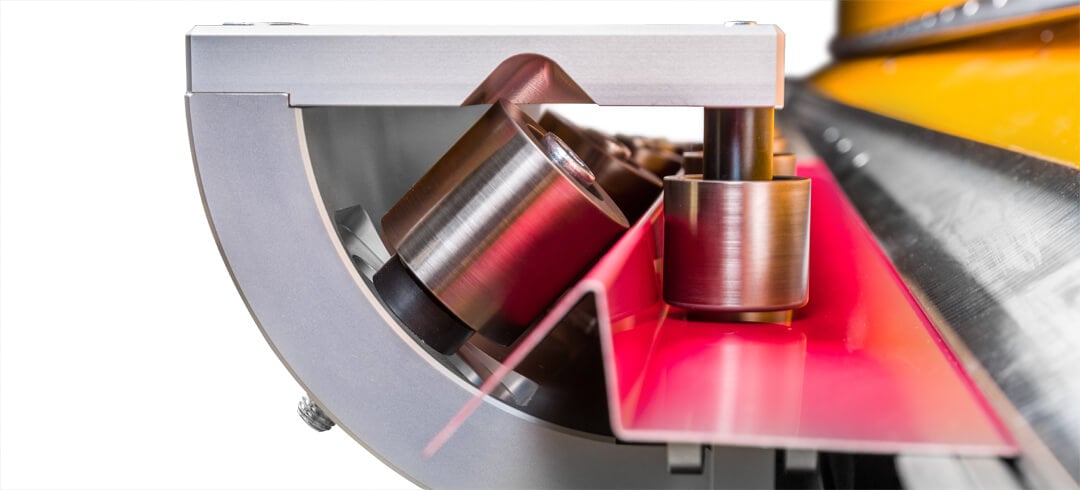

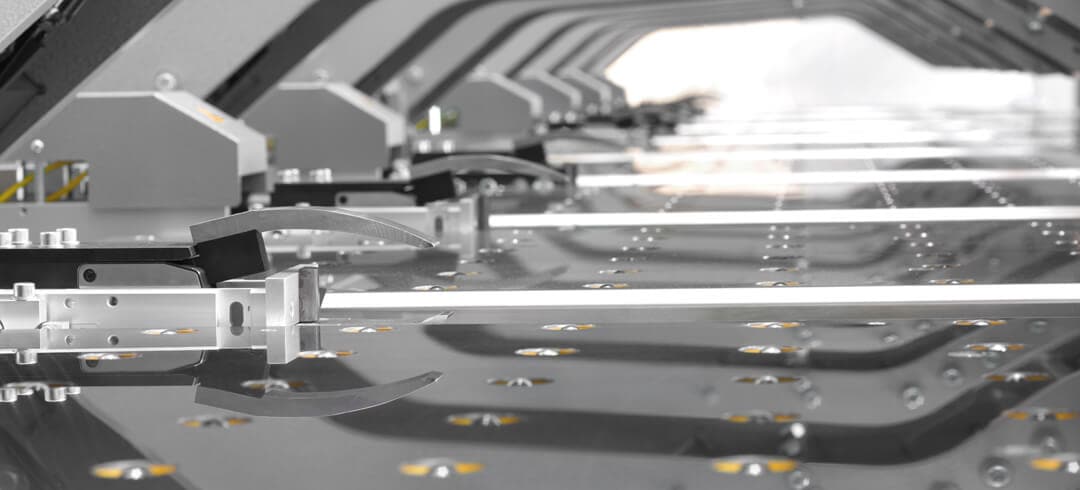

Based on the unique kinetic controlled synchronized shaft technology from Thalmann, which enables synchronous force distribution and unrestricted work performance over the entire length of the machine, the cost-efficient powerhouse folds even 3 mm thick steel sheet dynamically, quickly and accurately in both directions.

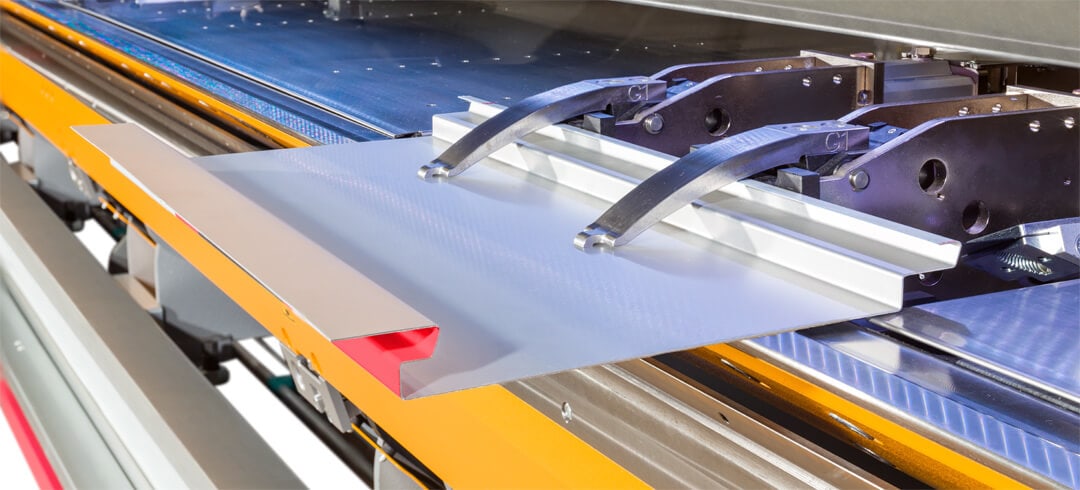

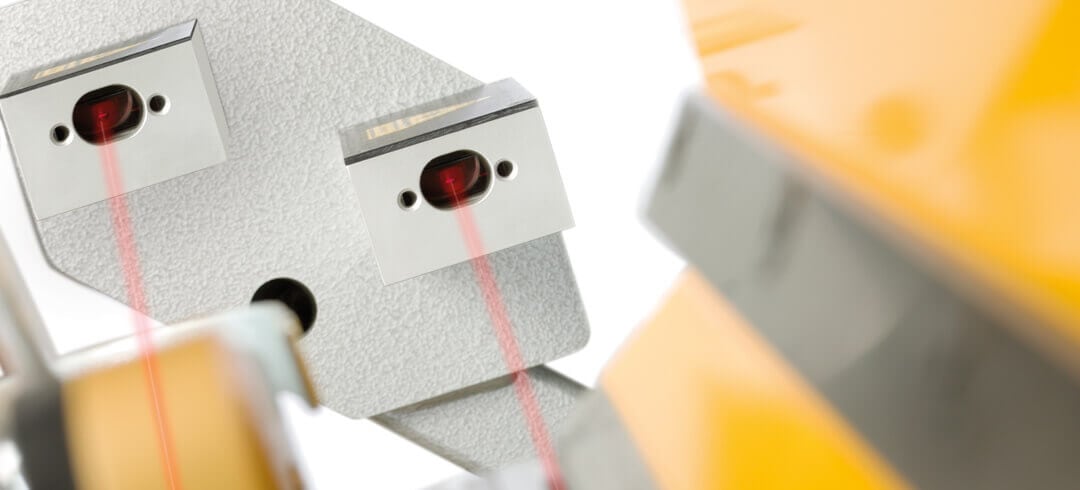

The exclusive vertical force drive (VFD) ensures the extremely high clamping force deployment. The high production speed with constant folding precision is based on dynamic folding technology (DFT).

The maximum insertion depth is 1250 mm and the standard length of the machines can vary from 3.20 meters to 12.00 meters. Different machine lengths can be custom produced upon request. The TC double folding machines can be fitted and costume designed with different accessories e.g. such as roll forming or cutting units.

Benefits

Reduction of PRODUCTION COSTS and an increase of PROFITABILITY

Increased PRODUCTIVITY and an increase of CAPACITY

Leaner WORK PROCESSES and improved PRODUCTION PLANNING

Ergonomic WORK ENVIRONMENT and sophisticated SAFETY DEVICES

Higher FOLDING PRECISION and faster FOLDING PROCESSES

Optimized FOLDING CLEARANCE and maximum FLEXIBILITY

Better PRODUCT QUALITY and a wider PRODUCT RANGE

Access to NEW MARKETS and securing COMPETITIVE ADVANTAGES

Minimal MAINTENANCE and LONG MACHINE LIFE

Integration of DIGITAL SOLUTIONS and open SOFTWARE INTERFACES

AUTOMATION SOLUTIONS and individual ADDITIONAL FUNCTIONS

Functions

Video

Machine Data